USE OF VERMICULITE

Due to its manifold uses, vermiculite's fields of application have not yet been exhausted. Vermiculite is a universally applicable clay mineral. Due to its special physical properties, it is used in the insulation industry, for fire and noise protection, as a transport packaging material and in horticulture. It is also used in hydroponics.

A special property of this mineral is its ability to exchange ions in the crystal lattice. In this process, potassium ions are replaced by hydrated calcium or magnesium ions. This property makes vermiculite particularly suitable for use in agriculture, forestry and horticulture, where it contributes significantly to soil fertility, and can be used as a composting aid or as a carrier material for fertilisers, herbicides or insecticides.

An important branch of application is the insulation industry. Due to its low thermal conductivity and low density when inflated, it is excellently suited as an insulating material, for example in sound and high-temperature areas, but also for fire protection and as a lining for various types of furnaces and blast furnaces.

Other possible applications are in the building materials industry, as an aggregate for cement, plasters and gypsum. Vermiculite is also suitable as a binder for spilled liquids, for example in the event of accidents.

Vermiculite is used in products that require strong heat insulation and is considered the best solution for fire protection. Vermiculite-based products range from boards and panels to premixed coatings such as sprayed plaster applications and hand-applied plaster applications.

Vermiculite plasters can be mixed with other inorganic compounds such as gypsum or cement. Vermiculite and cement can be used to produce a concrete with good thermal insulation and temperature resistance properties. Compared to conventional renders, vermiculite-based renders have the following advantages: improved hiding power, lighter weight, easier application, excellent fire resistance, lower thermal conductivity, improved adhesion to a wide range of substrates and increased resistance to cracking and shrinkage. Vermiculite particles have the ability to accept dimensional changes and are therefore less susceptible to damage. Whether gypsum- or cement-based, vermiculite plasters can be applied either by hand or by spraying with special machines. Due to its non-abrasive properties, vermiculite is particularly suitable for such spray applications and can also have a very decorative effect in this way.

Pores and cavities in masonry and hollow block buildings are filled with expanded vermiculite to improve sound insulation. Vermiculite has excellent airborne sound insulation properties due to its ultra-light, loose cast composition. Until now, heavy materials have been integrated into buildings for sound insulation. However, this is often difficult to do, especially in existing buildings. Vermiculite therefore represents a particularly suitable alternative for sound insulation and, with a minimum depth of 100 mm, falls into class "A".

The use of finer vermiculite grains is particularly widespread in the manufacture of brake pads. Vermiculite is highly suitable as a friction lining for brakes due to its heat resistance, ease of mixing with other raw materials to form a homogeneous compound, and its shape and surface properties.

Because it has excellent thermal protection properties as well as a low density and is easy to apply despite its natural heat resistance, vermiculite is particularly suitable for use in steel construction and foundries. It is used as a pourable insulating material for coating hot surfaces to reduce heat loss from the mould and ladle.

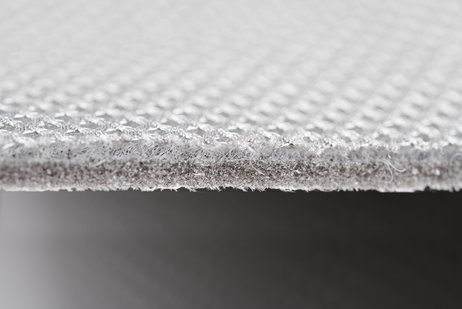

Vermiculite is mixed with other materials to make insulation boards. By filling cavities with vermiculite, it can also be used for insulation in housing construction. Due to its insulating properties, expanded vermiculite reduces heat loss during the cold season and keeps the house cool in summer. Due to its low thermal conductivity, vermiculite is also used in the form of thermal insulation boards or non-combustible board material in ship interior finishings and also in building construction.

Very valuable for plants in every stage of growth - strong seedlings, healthy cuttings and joyful growth are provable results. The use of vermiculite as a nutrient medium is widespread and is mainly used in combination with peat in compost mixtures. Compost compounds of vermiculite and peat provide ideal conditions for plant growth. The vermiculite particles in the compost promote air supply as well as moisture retention and support a consistent release of fertiliser. Vermiculite is one of the few natural aids that can absorb, store and release nutrients back to the roots. The vermiculite itself contributes to plant growth with potassium, magnesium and some other minor components. The ideal air-water ratio of peat vermiculite composts promotes the growth of healthy young plants and stimulates root formation. Processed vermiculite is sterile and, if handled correctly, requires no further processing for incorporation into compost compounds. Vermiculite can also be used as a carrier and filler for fertilisers, pesticides and herbicides, and in ground form also for seed encapsulation. It is used in the vegetable industry as a cover material for seedlings after sowing. It is light and has the ability to reflect light and retain moisture. This prevents excessive heating of the seedlings and ensures balanced substrate moisture.

Vermiculite is free-flowing, soft, sterile and absorbent. It is therefore particularly suitable as a carrier medium for many different nutrients such as fat concentrates, vitamin preparations and molasses. Vermiculite is an approved carrier material for the animal feed sector. Vermiculite is used industrially in cat litter. Vermiculite is also frequently used in reptile breeding and keeping, where constant humidity in the terrarium, wet boxes and incubator is vital for the animals, as it absorbs excess moisture, even from the air, and releases it again when needed.

Expanded vermiculite is widely used in the packaging industry. The advantages here are the low weight of the vermiculite, its purity and the ability to fit it easily around unusual shapes. In addition, it offers excellent protection against shocks in the event of impact or carelessness during transport, and its high absorbency safely absorbs any spills of potentially hazardous materials such as chemicals. Since vermiculite is inorganic and non-flammable, there is no risk of fire. It can therefore be used for packaging liquid hazardous materials. Expanded vermiculite can also be used as a packaging material for fruits, bulbs and root tubers. Since vermiculite is soft and does not chafe, it is also used for insulating and cushioning the bottom of swimming pools with plastic walls.

The cation exchange capacity of vermiculite (up to 80 - 100 me per 100g) also allows it to be used in the liquid treatment of wastewater as well as in chemical treatment and air pollution control in industry. In addition to its ion exchange capacity, vermiculite binds liquids both in the interlaminar pores of the individual particles and between the particles themselves.